About us

Über uns

Products

Produktpalette

Downloads

Downloads

The artificially created district near the centre of the Danish port city Aarhus offers spacious new living space. The latest construction project, “The Lighthouse,” contributes significantly to this by adding 400 new apartments to the housing market. As the name promises, the building rises majestically like a lighthouse on the southeastern shore of the harbour area, and it is also Denmark’s tallest residential building.

The building captivates with its unique architecture, especially the organic and geometric shapes of the roof, facades, and balconies. Particularly striking is the parallelogram footprint of the building, rounded on two opposite sides. The realization of this design was a challenge that Robert Thiebes of Kalzip mastered with confidence, using specialized software and on-site data collection. Particularly innovative are the diagonal standing seam profiles of the roof terrace, which allow for efficient rainwater drainage while also serving as a stylistic highlight. During the structural calculations, it was discovered that an additional floor was possible, perfectly suited for creating a sophisticated gastronomy and viewpoint for visitors at 142 meters above ground.

During the processing on the construction site, the team of the executing company AE Stålmontage a/s started at the highest point of the roof and initially moved on one half of the roof towards the roof terrace. The assembly proceeded as usual: The profiled panels were placed on top of each other at the seam and flanged with a flanging machine.

The installation of the complex, three-dimensionally curved Kalzip XT sheets with a corresponding angle of inclination proved to be particularly tricky. Despite the flexible substructure, which offered a little room for manoeuvre during installation, as well as the clearly laid out construction plans, construction was briefly halted, as Robert Thiebes reports: “In this project, there was only a few centimetres of displacement space between the profiled sheets, which decided whether the next sheet would fit in or wedge in. In order to find the best possible solution to this problem, we travelled to the construction site, were able to quickly locate the error and instructed the employees accordingly.”

Innovative techniques were necessary to implement the curved transition from the roof to the facade. Each individual standing seam profile of the building was numbered and prefabricated in advance, then specifically bent and twisted according to its designated location. As always, this required precise millimetre work, leaving no room for errors. The installation of the complex, 3D curved KALZIP XT panels with a certain angle of inclination posed the biggest challenge, as there was only a few centimetres of leeway for installation.

The “Lighthouse” presented special challenges during planning and construction, especially due to limited storage space because of the surrounding buildings and proximity to the water. Consequently, all materials were stored in the neighbouring port docks. Transporting the standing seam profiles from Koblenz to Aarhus was a logistical masterpiece. To protect the different angles of inclination of the profile panels, they had to be stacked on pallets with special spacers. A crane transported these pallets to the roof. Due to the height and resulting wind suction, the unused standing seam profiles had to be secured with tension straps.

With the completion of the roof, the exterior shell of the impressive “Lighthouse” building was finalized. The 480m² XT profiles from Kalzip, not visible to visitors, incorporate a sophisticated recess for a maintenance crane. “Despite the relatively small area, the ‘Lighthouse’ roof stands out for its unique and demanding shape, making it a complex and time-consuming challenge,” says Robert Thiebes.

Contact

Kalzip GmbH

Yannick de Beauregard

Kalzip Marketing

August-Horch-Str. 20 – 22

56070 Koblenz

Phone: +49 261 9834 0

Fax: +49 261 9834 100

E-Mail: yannick.de-beauregard@kalzip.com

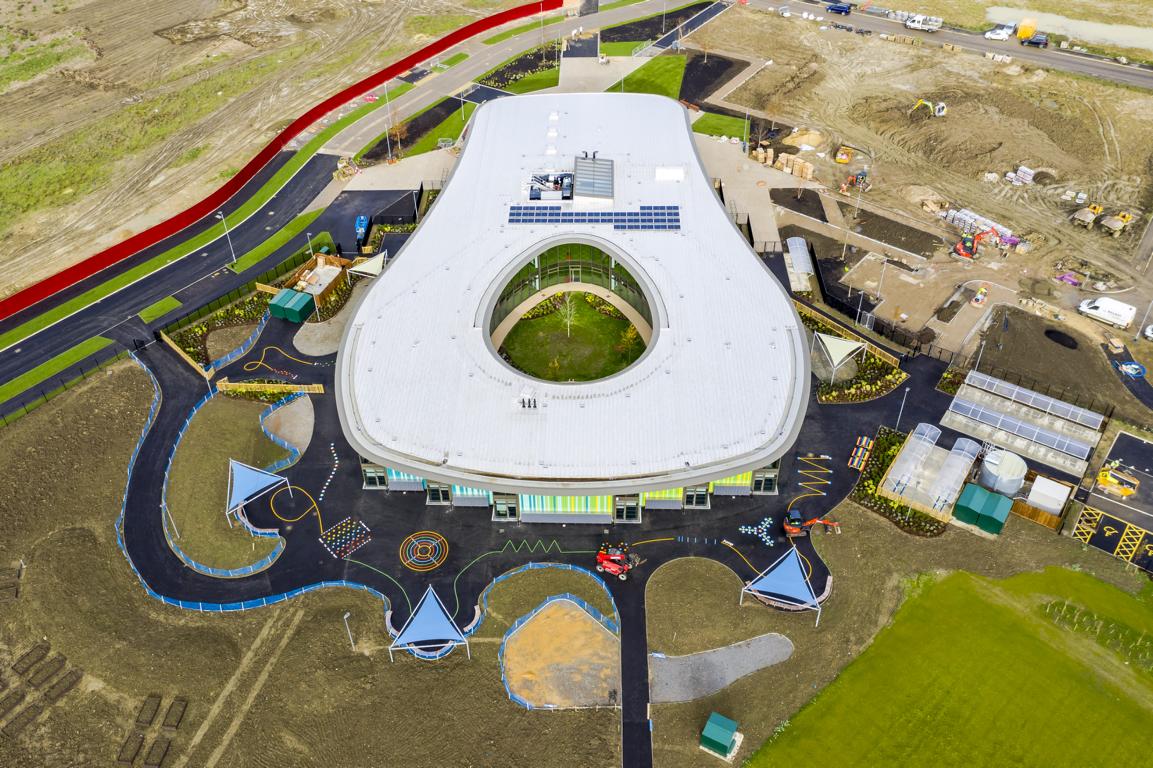

The township of Wintringham received a new flagship building in the form of Wintringham Primary Academy in St Neots, Cambridgeshire, completed in 2021. Cambridgeshire County Council commissioned the building affectionately known as the ‘Avocado’ due to its unique roof shape. The project is a clear demonstration of the excellence of workmanship that Kalzip provide to clients through the installation of the Kalzip standing seam roof system and the quality of the bespoke curved aluminium soffit and aluminium fabrications.

Philip Marsh, Founding Director at dRMM (de Rijke Marsh Morgan Architects), who was responsible for the school’s design, said: “Wintringham Primary Academy’s distinctive shape was formed by Passivhaus principles. By arranging teaching spaces around a central grove, the aim was to increase daylighting and cross ventilation from multiple aspects. The shape allows a spatial arrangement which supports the idea of a school ‘in the round’.

“The client required a roof system that was robust and low maintenance, and one that would stand the test of time. A Kalzip standing seam profile roof was selected after considering a few options, ultimately the Kalzip system provided the best option in terms of durability. Additionally, the Kalzip roof also offered compatible bolt-on solutions for roof maintenance systems that were easy to integrate. The project required a fall restraint mansafe system and roof access stair which could be simply incorporated as part of the roof system. From the moment we started liaising with Kalzip for their technical input they were most helpful and were able to answer all our technical queries in great detail.

“Kalzip 50/429, stucco embossed aluminium was specified for the project, which was site rolled at the eaves with the longest sheet measuring 72 metres. Additionally, intricate detail work was required on the curved aluminium fabrications, along with the drainage requirements on the complex roof shape. Having received high-level technical information at the early stages of enquiry, we were confident Kalzip’s experience would be beneficial. We also specified 280mm Kalzip insulation plus 40, compressed to 255mm within a cavity created by E180 clips, S5 & S10 spacer pads, galvanized steel top hat supports fastened down to a Glulam Beam timber structure to achieve the thermal requirements.”

There were some logistical challenges for this bespoke project, mostly surrounding the tight budget and construction programme. Just 12 months were allowed for the construction with completion to coincide with the start of the new school year. Kalzip’s systems are predominantly manufactured offsite, which led to a quick and simple installation onsite, despite the complex nature of the roof.

Wintringham Primary Academy is a prototype typology for an all-timber school that delivers an inspirational learning environment, which surrounds itself with greenery inside and out. To enhance wellbeing, dRMM prioritised a timber aesthetic, natural light, ventilation and direct access to the surrounding landscape in response to the school’s affinity with forest school principles.

As part of a team headed by contractor Morgan Sindall, dRMM worked with Cambridgeshire County Council (CCC) and the Diamond Learning Partnership Trust (DLPT) to develop the vision. This called for a three-form entry primary school for up to 708 children, including a nursery that could be run independently if required. The 3615m2 school was completed in 2021 after a construction programme of just 14 months despite the restrictions of the pandemic.

There were a number of challenges to overcome, and Kalzip’s vast experience was certainly required at numerous points. As a result, Kalzip was awarded Morgan Sindall’s ‘Perfect Delivery” award for the Wintringham Primary Academy project. Wintringham also achieved the RIBA East Regional Award and the RIBA East Sustainability Award in 2022 and was highly commended in the Structural Timber Awards.

For more information please visit: www.kalzip.com/en/

Contact

Kalzip GmbH

Yannick de Beauregard

Kalzip Marketing

August Horch St. 20 – 22

56070 Koblenz

Phone: +49 261 9834 0

Fax: +49 261 9834 100

E-mail: yannick.de-beauregard@kalzip.com

With the company Sperber Klempner GmbH & Co. KG, Jens Sperber set up his own business at the beginning of the 1990s. Over the past few years, the family business has become a specialist in handcrafted and industrial metal roofing and façade cladding of all kinds. With its 15 employees, the specialist company realises many projects.

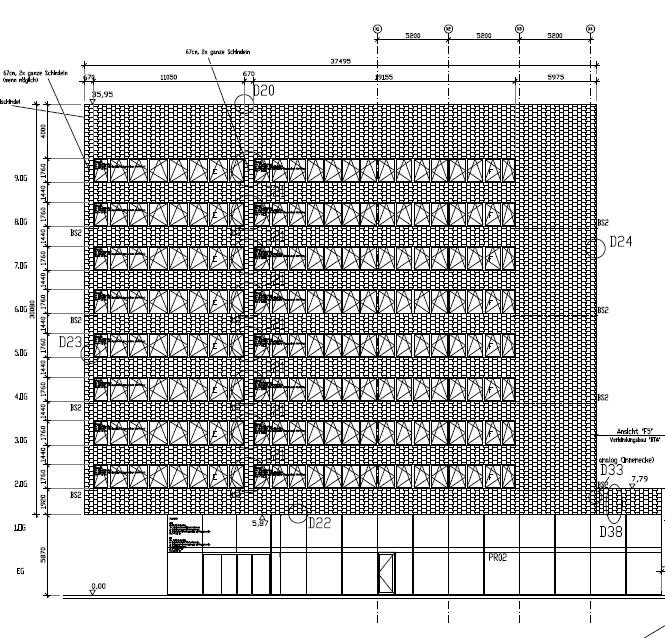

With the Nordkopf Tower in Wolfsburg, the Kalzip PremiumPartner from Unterwellenborn, Thuringia has now been able to realise an exceptional project. Kalzip aluminium shingles with an anodised titanium coating were used for the façade cladding.

Mr Sperber, your company is responsible for a wide variety of projects throughout Germany – from single-family homes to large-scale projects. How does the Nordkopf Tower rank among your references?

Sperber: The Nordkopf Tower is an extraordinary project, unique for our company in terms of its scale and nature. To put it in figures: We are talking about two construction phases with about 5,875 m2 of façade surface, which is completely clad with aluminium shingles.

Our team had to measure the façade area with specially purchased laser technology. This complex process alone, the planning and measuring, took about 1000 working hours. In the end, a total of around 58,500 individually manufactured shingles were installed on the project.

What challenges did you face in the project and how did you solve them?

Sperber: The architects’ specifications and wishes regarding the arrangement of the shingles challenged us in terms of planning. The shingles were to take up the dimensions of the planned building structure in such a way that all connections and terminations open up with a whole shingle. So first of all we had to design the shingle onto the building envelope, not only paying attention to the dimensions of the façade, but also taking into account the height and width of all the windows.

Together with Hans-Jürgen Löffler, who takes care of the planning of projects for us, we created a 3D plan – without this cooperation we would not have been able to realise the project without any waste. Not a single shingle was cut or adjusted on site, thanks to the excellent pre-planning.

You had already mentioned that the shingles were made individually. Was there no machine solution here?

Sperber: After our measurements and the projection onto the façade surface as well as several mock-ups, the shingles had to be manufactured in a special size of 320 x 345 mm. In this project, despite many reservations on the part of those involved, we processed the complete shingles without protective film, from processing to installation; this would not have been possible by machine. Also under the aspect of the clear additional expenditure with the removal of the foil and above all also the special waste on the building site, we had the shingles of the 1st construction phase edged and manufactured by hand in a workshop for the disabled in Fambach.

The shingles for the second construction phase were manufactured in our company. The titanium silver is also a very scratch-resistant hard colour, so the risk of noticeable scratches was very low. The client’s goal was to realise the entire building project in a sustainable manner and ultimately also to receive the gold certificate from the DGNB for the implementation.

The building consists of an old building that has been supplemented by a new part with the intention that this circumstance is no longer visible. What had to be taken into account during the execution so that both parts of the building visually merge with each other?

Sperber: It was less of a problem in the planning than in the execution, as all the dimensions of the new building were available. After gutting the old building, we suddenly had to compensate for a difference of 6 centimetres. At the same time, the corners of the building were not to be finished with angle strips, but also with shingles edged in the grid, so there was no room for manoeuvre here. Our only advantage:

The shingles were to overlap each other about halfway in order to achieve the shingled structure in the surface. This way, the team could work with a certain amount of shifting space, so to speak, and compensate for the unplanned 6 cm difference.

In your opinion, what influence does the façade have on the overall building?

Sperber: Both the laying direction and the colouring contribute to the surface appearance. Depending on the angle of view, the metallic surface has a different appearance. Sometimes it is the square outlines of the cladding elements, sometimes a continuous flat stair pattern in the field of vision. Due to the titanium-coloured coating and the gloss level of the aluminium shingles, the building reflects the surrounding light situation. In addition, the alignments are designed in such a way that the building blends into its urban surroundings.

Which memory stands out in your mind?

Sperber: A special highlight for our company: the architects of the Nordkopf Tower invited us to the 2018 Venice Biennale. We clad the room, where the model was also exhibited, with specially made shingles. In addition, the building project was awarded the title “Building of the Year 2018” by German Architects.

Jens Sperber, thank you very much for the interview!

Kontakt

Kalzip GmbH

Yannick de Beauregard

Kalzip Marketing

August-Horch-Str. 20 – 22

56070 Koblenz

Phone: +49 261 9834 0

Fax: +49 261 9834 100

E-Mail: yannick.de-beauregard@kalzip.com

Functional cookies are absolutely necessary for the proper functioning of the website. This category only includes cookies that ensure basic functionalities and security features of the website. These cookies do not store any personal information.

Statistical cookies are used to understand how visitors interact with the website. These cookies help provide information about metrics such as number of visitors, bounce rate, source of traffic, etc.

Marketing cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customised ads.