ACOUSTIC PERFORMANCE IN SCHOOLS

In contrast to many other sectors, there is detailed acoustic performance guidance for educational buildings. Here Adrian Whitefoot, Technical Services Manager at Kalzip, looks at the requirements of Building Bulletin 93 and how the correct specification of building envelope solutions can help achieve these.

In contrast to many other sectors, there is detailed acoustic performance guidance for educational buildings. Here Adrian Whitefoot, Technical Services Manager at Kalzip, looks at the requirements of Building Bulletin 93 and how the correct specification of building envelope solutions can help achieve these.

Ensuring good acoustics and minimising levels of noise in school environments is essential. A growing body of evidence has shown the impact of noise on academic performance and cognitive development. For example, a recent study from the Barcelona Institute for Global Health found that higher levels of traffic noise caused slower development in memory and attention among children aged 7 to 10.

A quiet place for children gives the best surrounding for an ideal learning environment. (© KGM Roofing)

The main source of legislation for acoustics is Approved Document E of the Building Regulations, and in particular section E4, which specifically relates to acoustics in schools. For guidance on achieving the required acoustic conditions, Approved Document E refers to Building Bulletin 93 (BB93), the guide for acoustic design published by the Department for Education. While section E4 of the Building Regulations does not apply to colleges and universities, the acoustic recommendations provided in BB93 may also be desirable in these environments and therefore can provide a design standard.

Building Bulletin 93 sets limits for the level of ambient noise in rooms and spaces within a school based on how it is used. For example, the limit in classrooms and general teaching areas in primary and secondary schools, including those used for music and drama, is 35dB LAeq,30mins for new buildings and 40dB LAeq,30mins for refurbished buildings. Higher limits are set for sports halls, dance studios and swimming pools, while lower limits are given for teaching spaces for students with special hearing and communication needs.

Noise pollution can come from a wide range of sources, especially in school environments. External sources include aircraft, traffic, rain impact, noise from playgrounds and outdoor sports, and sound transmitted from nearby school buildings. Internally, impact and airborne sound from students and teaching activities can be transferred between floors and through walls.

Noise reduction can be easily achieved with the use of the Kalzip Accoustic roof.

Noise reduction can be easily achieved with the use of the Kalzip Accoustic roof.

There are a number of measures that can be implemented in the specification of building envelope systems to improve the acoustic performance of both new build and refurbishment projects. Different insulation materials will have varying acoustic properties but one of the most effective methods for increasing sound insulation of roofing and facades is to increase the mass of the system. Its performance is governed by the ‘mass law’, which states that the sound insulation of a solid element will increase by approximately 5 dB per doubling of mass. With metal roofing systems this can be achieved by adding different densities and thicknesses of mineral wool or rigid slab insulation. Alternatively, for higher performance scenarios, various thicknesses of cementitious board can be introduced as part of the façade or roof build up. As a built-up solution, aluminium roofing and façade systems offer this flexibility to tailor the specification to meet the acoustic requirements.

In addition, acoustic and dampening membranes can also be used to increase sound insulation. For example, to reduce the sound of rain noise, an anti-drumming membrane can be bonded to the underside of an aluminium roofing system to achieve approximately a 6 dB reduction in sound intensity.

Controlling sound within teaching spaces must also be considered carefully when designing educational facilities. Excessive sound reverberation within a classroom can distort speech and make teaching and communication difficult. Building Bulletin 93 provides guidance on acceptable reverberation times (RT) depending on the intended use of the space. For example, for a new build nursery room or general purpose primary school classroom it is ≤ 0.6 seconds. In contrast, the same type of teaching space in a secondary school would only need to achieve a RT of ≤ 0.8 seconds. The correct specification of roofing and façade systems can help to minimise excessive reverberation as well. Perforated liners and structural decks can be introduced as part of the roof build-up to diffuse sound where improved sound absorption performance is required.

The Kalzip Accoustic roof is based on the proven Kalzip technology with the same flexibility.

Achieving the optimum specification to ensure acoustic targets are met alongside all other building performance and design requirements can be complex. That is why it is important to partner with a roofing and façade system manufacturer that can offer a wide array of solutions as well as technical support services. Leading manufacturers, such as Kalzip, will be able to use laboratory test reports and data from previous projects to provide specification guidance and assess the performance of a proposed system.

Ensuring the acoustic performance of school buildings is essential to provide an environment that supports learning and development. Building Bulletin 93 provides detailed guidelines, which the correct specification of building envelope materials and systems can help achieve.

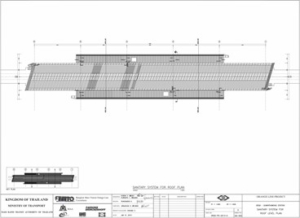

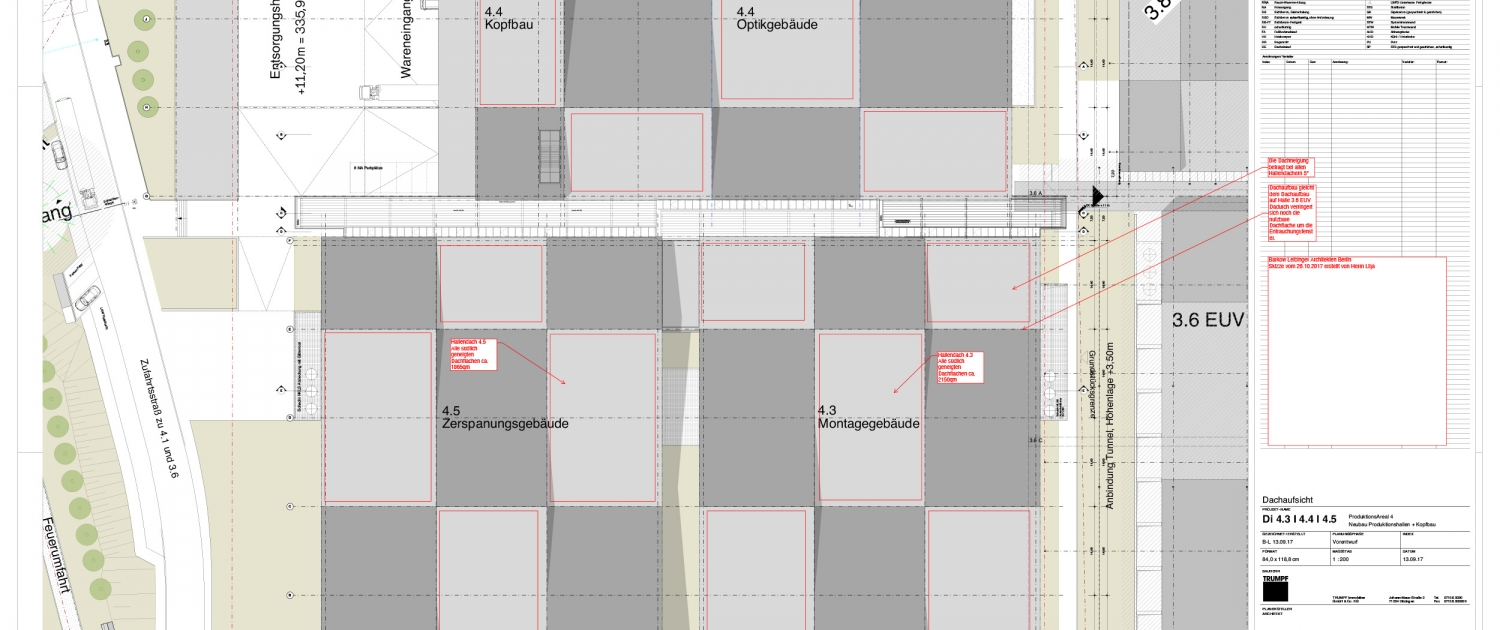

The company premises of TRUMPF in Ditzingen near Stuttgart

The company premises of TRUMPF in Ditzingen near Stuttgart The design from the Architekturgesellschaft Barkow Leibinger is playing with contrary angles

The design from the Architekturgesellschaft Barkow Leibinger is playing with contrary angles Appearance and function are going hand in hand

Appearance and function are going hand in hand The dimension of the solar modules as a challenge on the construction side

The dimension of the solar modules as a challenge on the construction side The German Air Traffic Control campus in Kaufbeuren

The German Air Traffic Control campus in Kaufbeuren Here, the future air traffic controllers and flight advisors will find ideal training conditions

Here, the future air traffic controllers and flight advisors will find ideal training conditions Oriented towards the region and yet completely independent in its aesthetics

Oriented towards the region and yet completely independent in its aesthetics Clear edges as far as the eye can see. They characterise the design by Henn Architekten-Ingenieure.

Clear edges as far as the eye can see. They characterise the design by Henn Architekten-Ingenieure. This is how light metal can seem. The perforated Kalzip profiles create a play of transparency.

This is how light metal can seem. The perforated Kalzip profiles create a play of transparency.