Pont piétonnier à Pickering, Canada

A pied sur le pont du record du monde

Le « Pickering GO Pedestrian Bridge » dans la ville canadienne de Pickering permet aux piétons de se rendre en toute sécurité de la gare située au sud au centre-ville situé au nord. Avec son enveloppe extérieure illuminée la nuit par Kalzip, il attire tous les regards.

L’enveloppe extérieure a été installée par sections pendant la nuit, de sorte que l’autoroute n’a pas eu à être fermée pendant la journée. (Photos : Kalzip GmbH)

La passerelle de Pickering, au Canada, est déjà en train de devenir l’emblème de la ville : avec une longueur de 250 mètres, elle est entrée dans le livre Guinness des records en 2021 en tant que plus longue passerelle couverte du monde. La portée s’étend sur six voies de chemin de fer ainsi que sur l’autoroute 401, l’une des autoroutes les plus fréquentées du nord des États-Unis et du Canada avec ses 14 voies. Afin d’offrir aux visiteurs de la gare Pickering GO une liaison directe et sûre vers le quartier situé en amont de l’autoroute, avec son centre commercial et son collège local, les gouvernements fédéral et provincial ainsi que l’entreprise de transport locale Metrolinx ont lancé le projet de passerelle. L’enveloppe visible de Kalzip confère au tunnel de surface des formes organiques. Le soir, les profilés à joint debout sont illuminés et rendent ainsi l’ouvrage clairement visible depuis l’espace aérien.

Organique et inorganique à la fois : la passerelle métallique pour piétons se faufile sur l’autoroute 401 comme une veine (Photos : Kalzip GmbH)

Perforation pour la lumière

La passerelle est une construction en treillis métallique avec un sol en béton et un toit en acier. Habituellement utilisés comme enveloppe de bâtiment aquifère, les profilés à joint debout 65/305 de Kalzip ont été utilisés ici pour un pur effet optique. Les panneaux à joint debout cintrés de manière convexe sont perforés de trous ronds de 6 mm de diamètre espacés de 8 mm. Grâce à la légère transparence, les utilisateurs de la passerelle bénéficient d’une part de la lumière naturelle et d’une protection contre le rayonnement solaire direct, et d’autre part d’une vue sur l’autoroute 401. La surface perforée permet en outre d’illuminer la passerelle avec des bandes lumineuses LED vers l’intérieur et l’extérieur.

En raison de la forme complexe du pont, la structure porteuse en acier a d’abord été scannée à l’aide d’un capteur LiDAR terrestre. Les données obtenues servant de base, un planning a pu être établi chez Kalzip afin de pouvoir plier et découper les profilés à joint debout en fonction du tronçon et de la courbure.

Les parties exposées offrent une vue dégagée sur l’autoroute et la campagne environnante. Les panneaux profilés captent les jeux de lumière colorés. (Photo : Kalzip GmbH)

Construction avec obstacles

Outre les calculs et les plans de construction, Kalzip a également fourni la matière première en bobines ainsi qu’une installation de formage mobile. Une équipe composée de collaborateurs américains et d’un collaborateur allemand a utilisé l’installation de formage à rouleaux et a ainsi fabriqué sur place les profilés à joint debout de longueur appropriée. La machine peut être ajustée à la forme et à la largeur de profilé souhaitées et offre en outre la fonction de plier les panneaux profilés finis selon un rayon prédéfini.

Un défi un peu plus grand s’est toutefois posé lors du montage des profilés à joint debout. Pour permettre les travaux sur le pont à l’extérieur, les voies de circulation de l’autoroute ont dû être partiellement fermées. Une grande partie des travaux a donc été effectuée de nuit afin de ne pas perturber inutilement cet important axe de circulation. Le montage des panneaux profilés s’est également déroulé différemment de d’habitude : au lieu de se chevaucher au niveau des joints debout, les panneaux ont été fixés à la structure métallique de manière légèrement décalée. Ainsi, selon les sections et l’angle de vue, on obtient une légère structure étagée.

Argenté le jour, multicolore la nuit

Après une dizaine d’années au total, de la planification initiale à la construction finale, le pont a été achevé en 2018. L’architecture devient un point fort, surtout dans l’obscurité du soir et de la nuit. Environ 300 lumières LED bordent le chemin piétonnier et mettent en scène les formes organiques. Les couleurs des lumières varient entre le violet, le violet, le bleu et le pétrole. Grâce au revêtement en patine Aluplus et à la perforation, le jeu de lumière est transmis vers l’intérieur et l’extérieur. En 2019, l’ouvrage a reçu le « Urban Design Award » de la ville de Pickering.

(Photos : Kalzip GmbH)

Une réflexion approfondie. KALZIP.

Contact

Kalzip GmbH

Yannick de Beauregard

Kalzip Marketing

August-Horch-Str. 20 – 22

56070 Koblenz

Phone: +49 261 9834 0

Fax: +49 261 9834 100

E-Mail: yannick.de-beauregard@kalzip.com

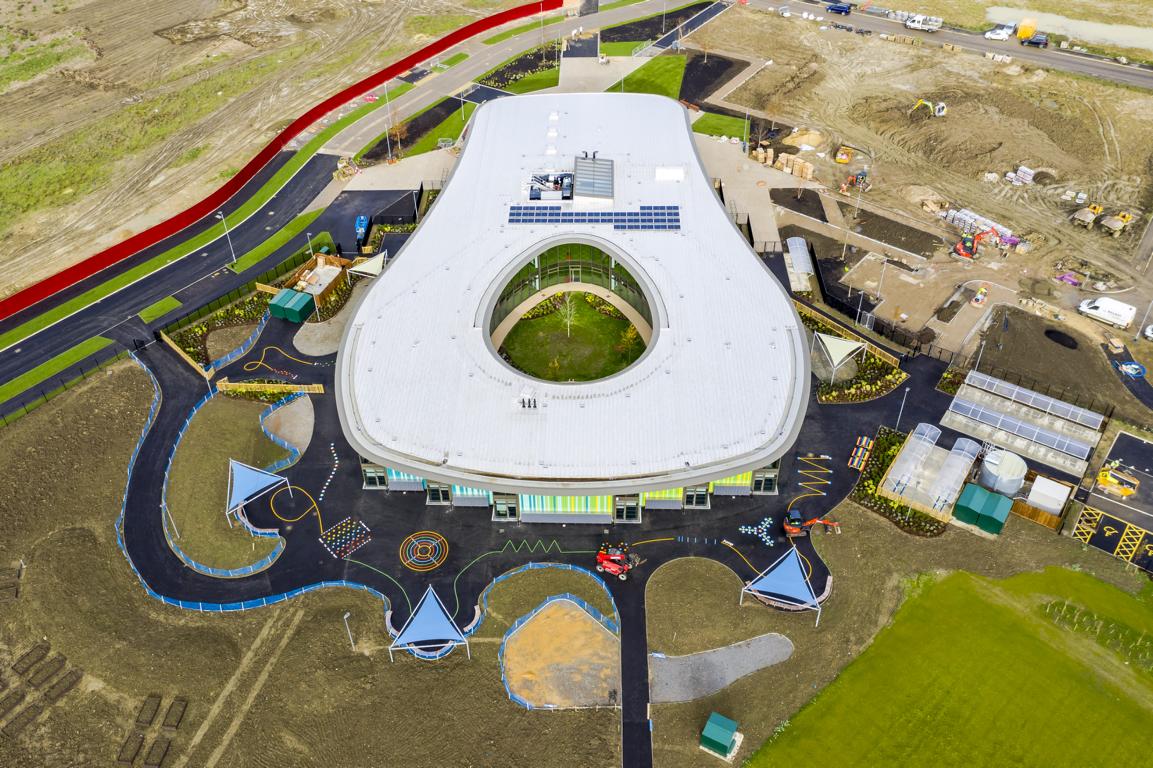

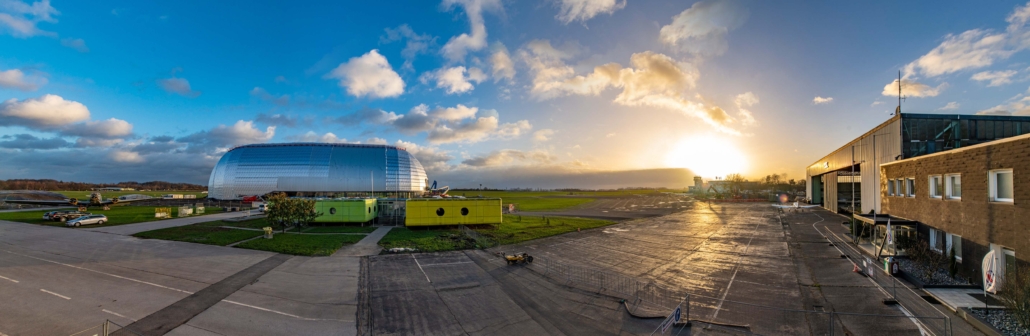

In contrast to many other sectors, there is detailed acoustic performance guidance for educational buildings. Here Adrian Whitefoot, Technical Services Manager at Kalzip, looks at the requirements of Building Bulletin 93 and how the correct specification of building envelope solutions can help achieve these.

In contrast to many other sectors, there is detailed acoustic performance guidance for educational buildings. Here Adrian Whitefoot, Technical Services Manager at Kalzip, looks at the requirements of Building Bulletin 93 and how the correct specification of building envelope solutions can help achieve these.

Noise reduction can be easily achieved with the use of the Kalzip Accoustic roof.

Noise reduction can be easily achieved with the use of the Kalzip Accoustic roof.